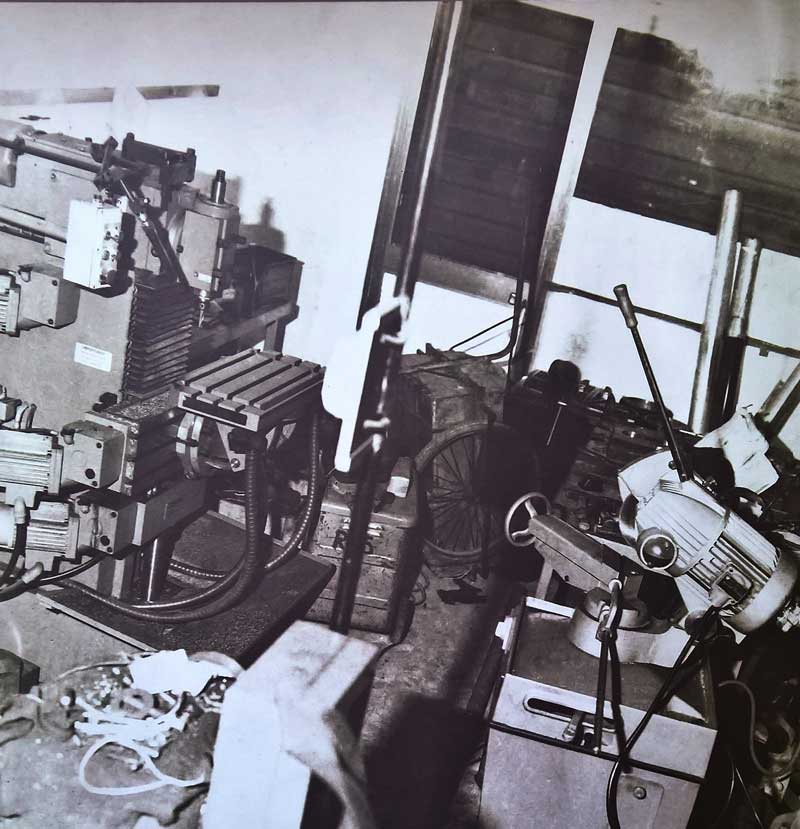

2M was founded in 1974 by Antonio Messori e Ivan Margini. In this period, 2M designs and develops plastic components for long-established local companies. The first orders come from the agricultural and zootechnical sectors.

During the Eighties, also due to the economic crisis which affected its core activities, the company decided to change its strategy to ensure greater diversification.

The relationships with different sectors and industries – together with the building of the first production plants – led the company to expand its skills in terms of knowledge of materials and technological expertise, while at the same time improving its quality and timeliness of service.

Today, 2M is an efficient and dynamic organisation capable of designing and manufacturing innovative solutions for an international clientele.

2M is a UNI EN ISO 9001 certified organisation since 1998

The company property covers an area of 10,000m2

The roof of the factory is covered with solar panels

Working with a focus on continuous improvement, the company has introduced a strict Quality Control system to ensure accuracy and repeteability.

Our Quality Management System has been certified by Kiwa as compliant with the international standards established by UNI EN ISO 9001:2015.

Our Quality Management System has been certified by Kiwa as compliant with the international standards established by UNI EN ISO 9001:2015.

Comprehensive management of the entire process, from technical consulting in the design and manufacturing stages to the finished product.

The relationships with different sectors and industries have led the company to expand its skills in terms of knowledge of materials and technological expertise.

2M stands out for its extreme flexibility in terms of project development, customisation (materials – dimensions – properties) and product performance.

Our in-house moulding department has a wide range of injection moulding machines –25t to 1400-tons presses – complete with robotic manipulators, ultrasonic welders, machine tools and pad printing machines.

Drawing upon its comprehensive knowledge and target investments in technology, 2M moulds a wide range of plastic materials from commodities to technopolymers and superpolymers.

Thanks to its large and well-organised warehouse, 2M guarantees competitive lead-times and delivery schedules agreed with the customer.